实验十 计算机控制综合应用实验之二

电热箱闭环控制实验

一 实验目的:

1.了解温度闭环控制方法

2.了解 PID 控制的规律及算法

3.了解计算机应用的闭环系统结构

二 实验设备

TDN86+ 教学实验系统

电热烤箱

三 实验原理

1.实验原理及接线

2.实验连线图

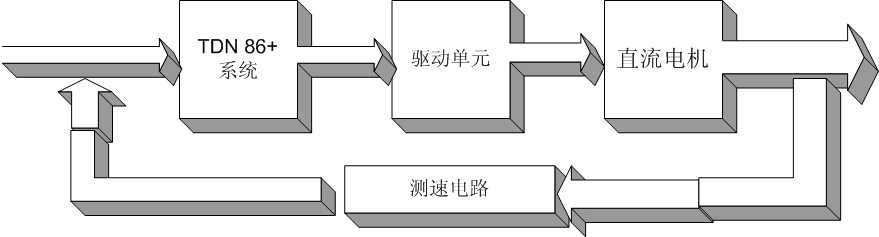

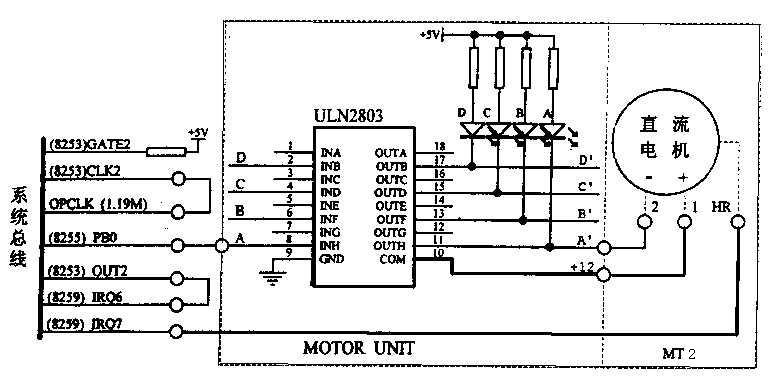

系统的 8255 B口的 PB0输出 PWM 脉冲信号为控制量,经驱动电路控制固态继电器的吸合以达到给烤箱升温的效果。温度测量使用了 10K 热敏电阻,经 A/D 转换构成反馈量,在参数给定的情况下,经 PID 运算产生相应的PWM脉冲控制量,使烤箱温度升温并稳定在给定值。OPCLK 为 1.193 MHz 时钟信号,经 8253 的 2 号通道分频输出 10 ms 的方波,一方面作为 A/D 的定时启动信号,另一方面接入 8259 的 IRQ6 产生中断,作为系统采样时钟。

烤箱温度控制范围在室温~ 250℃,不要过高,即设定 SPEC 范围在 14H(20℃)~ FAH (250℃ )之间,参考程序中设定温度为100℃ (SPEC = 64H)。采样参数为 100,即TS设为 64H,由于 8253 OUT2 接IRQ6 中断为 10 ms,故采样周期为1秒 (64 H* 10 = 1s)。 温度控制响应时间较长,一般一屏不能完全观测到整个响应过程,这样就需要更新显示,每增加一屏,实际控制时间要累加前面的。

3参考程序(提供的参考程序略有不足,可参考实验九的参考程序注释)(A20-2.ASM)

STACK

SEGMENT STACK

DW 256 DUP(?)

TOP LABEL WORD

STACK

ENDS

DATA SEGMENT

TS DB

64H

SPEC DW

0064H

IBAND DW

0060H

KPP DW 1F60H

KII DW 0010H

KDD DW 0020H

CH1 DB ?

CH2 DB ?

YK DW ?

CK DB ?

TC DB ?

TKMARK

DB ?

ADMARK DB ?

ADVALUE DB ?

FPWM DB ?

CK_1 DB ?

EK_1 DW ?

AEK_1 DW ?

BEK DW ?

AAAH DB ?

VAA DB ?

BBBL DB ?

VBB DB ?

R0 DW ?

R1 DW ?

R2 DW ?

R3 DW ?

R4 DW ?

R5 DW ?

R6 DW ?

R7 DB ?

R8 DW ?

TABLE DB

14H,14H,14H,14H,14H,14H,14H,14H,14H,14H,15H,16H,17H,18H

DB 19H,1AH

DB

1BH,1CH,1DH,1EH,1EH,1FH,20H,21H,23H,24H,25H,26H,27H,28H,29H,2AH

DB

2BH,2CH,2DH,2EH,2FH,31H,32H,32H,33H,34H,35H,36H,37H,38H,39H,3AH

DB

3BH,3CH,3DH,3EH,3FH,40H,42H,43H,44H,45H,46H,47H,48H,49H,4AH,4BH

DB

4CH,4DH,4EH,4FH,50H,4FH,50H,51H,52H,53H,54H,55H,56H,57H,58H,59H

DB

5AH,5BH,5CH,5DH,5EH,5FH,60H,61H,62H,63H,64H,64H,65H,65H,66H,66H

DB

67H,68H,69H,6AH,6BH,6CH,6DH,6EH,6EH,6FH,6FH,70H,71H,72H,73H,74H

DB

75H,76H,77H,78H,79H,7AH,7BH,7CH,7DH,7EH,7FH,80H,81H,82H,83H,84H

DB

84H,85H,86H,87H,88H,89H,8AH,8BH,8CH,8EH,8FH,90H,91H,92H,93H,94H

DB

95H,96H,97H,98H,99H,9AH,9BH,9BH,9CH,9CH,9DH,9DH,9EH,9EH,9FH,9FH

DB

0A0H,0A1H,0A2H,0A3H,0A4H,0A5H,0A6H,0A7H,0A8H,0A9H,0AAH,0ABH,0ACH

DB

0ADH,0AEH,0AFH

DB

0B0H,0B0H,0B1H,0B2H,0B3H,0B4H,0B4H,0B5H,0B6H,0B7H,0B8H,0B9H,0BAH

DB

0BBH,0BDH,0BEH

DB

0BEH,0C1H,0C2H,0C3H,0C4H,0C5H,0C6H,0C8H,0CAH,0CCH,0CEH,0CFH,0D0H

DB

0D1H,0D2H,0D4H

DB

0D5H,0D6H,0D7H,0D8H,0D9H,0DAH,0DBH,0DCH,0DDH,0DEH,0E3H,0E6H,0E9H

DB

0ECH,0F0H,0F2H

DB

0F6H,0FAH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH

DB

0FFH,0FFH,0FFH

DB

0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH,0FFH

DB

0FFH,0FFH,0FFH

DATA ENDS

CODE

SEGMENT

ASSUME CS:CODE,DS:DATA

START: MOV AX,DATA

MOV DS,AX

CALL INIT ;Initiate

STI

M1: CMP TKMARK,01H

;Judge Ts=Tc ?

JNZ M1

MOV TKMARK,00H

M2: CMP ADMARK,01H

JNZ M2

MOV ADMARK,00H

MOV AX,0000H

MOV AL,ADVALUE

MOV BX,OFFSET TABLE

ADD BX,AX

MOV AL,[BX]

MOV YK,AX

CALL PID

;Count Ck

MOV AL,CK

;Translate Ck into PWM

SUB AL,80H

JC IS0

MOV

JMP COU

IS0: MOV AL,00H

MOV

COU: MOV

SUB AL,AAAH

MOV

MOV AX,SPEC

;SPEC to CH1

MOV CH1,AL

MOV AX,YK

;YK to CH2

MOV CH2,AL

CALL PUT_COM

;Display Wave

JMP M1

PUT_COM:

MOV AL,31H

OUT 0C1H,

MOV AL,CH1

OUT 0C0H,

WAIT1: IN

TEST AL,01H

JZ WAIT1

MOV AL,CH2

OUT 0C0H,

WAIT2: IN

TEST AL,01H

JZ WAIT2

MOV AL,34H

OUT 0C1H,

RET

INIT: NOP

PUSH DS

XOR

AX,AX

MOV

DS,AX

MOV

AX,OFFSET

IRQ6 ;8259 IRQ6(T0:10ms)

ADD AX,2000H

;LOAD IP adress=2000H

MOV SI,0038H

MOV [SI],AX

MOV AX,0000H

MOV SI,003AH

MOV [SI],AX

MOV AX,OFFSET IRQ7 ;8259 IRQ7(INT0:Get ADvalue)

ADD AX,2000H

;LOAD IP adress=2000H

MOV SI,003CH

MOV [SI],AX

MOV AX,0000H

MOV SI,003EH

MOV [SI],AX

CLI

POP DS

IN AL,21H

AND

OUT 21H,AL

MOV

CK,00H

MOV

YK,0000H

MOV

CK_1,00H

MOV

EK_1,0000H

MOV

AEK_1,0000H

MOV

BEK,0000H

MOV

BBBL,00H

MOV

VBB,00H

MOV

R0,0000H

MOV

R1,0000H

MOV

R2,0000H

MOV

R3,0000H

MOV

R4,0000H

MOV

R5,0000H

MOV

R6,0000H

MOV

R7,00H

MOV R8,0000H

MOV TKMARK,00H

MOV FPWM,01H

MOV ADMARK,00H

MOV ADVALUE,00H

MOV AAAH,7FH

MOV VAA,7FH

MOV TC,00H

MOV AL,80H

;Initiate

8255-B(out)

OUT 63H,AL

OUT 1FH,

MOV

OUT 43H,AL

MOV AL,69H

;10ms

OUT 42H,AL

MOV

OUT 42H,AL

RET

SYSTEM:

MOV AL,76H

OUT 43H,AL

MOV

OUT 41H,AL

MOV AL,00H

OUT 41H,AL

MOV AL,00H

OUT 0C1H,

CALL DALLY

OUT 0C1H,

CALL DALLY

OUT 0C1H,

CALL DALLY

OUT 0C0H,

CALL DALLY

OUT 0C0H,

CALL DALLY

MOV AL,40H

OUT 0C1H,

CALL DALLY

MOV

OUT 0C1H,

CALL DALLY

MOV AL,34H

OUT 0C1H,

CALL DALLY

IN AL,21H

OR

AL,01H

OUT 21H,AL

RET

DALLY: NOP

PUSH CX

MOV CX,3000H

B2: PUSH AX

POP AX

POP

CX

RET

IRQ7: NOP

PUSH AX

IN

MOV

MOV ADMARK,01H

MOV AL,20H ;Close IRQ7

OUT 20H,AL

POP AX

IRET

IRQ6: NOP

PUSH AX

OUT 1FH,

MOV AL,TC

CMP

JNC TT2

INC TC

TT1: CALL

KJ

MOV AL,20H

;Close IRQ6

OUT 20H,AL

POP AX

IRET

TT2: MOV TKMARK,01H

MOV TC,00H

JMP TT1

KJ: NOP

PUSH AX

CMP FPWM,01H

JNZ TEST2

CMP VAA,00H

JNZ ANOT0

MOV FPWM,02H

MOV AL,BBBL

CLC

RCR AL,01H

MOV

JMP TEST2

ANOT0:

DEC VAA

MOV AL,01H

OUT 61H,AL

TEST2:

CMP FPWM,02H

JNZ OUTT

CMP VBB,00H

JNZ BNOT0

MOV FPWM,01H

MOV AL,AAAH

CLC

RCR AL,01H

MOV

JMP OUTT

BNOT0:

DEC VBB

MOV AL,00H

OUT 61H,AL

OUTT: POP

AX

RET

PID: MOV

AX,SPEC

SUB AX,YK

MOV R0,AX

MOV R1,AX

SUB AX,EK_1

MOV R2,AX

SUB AX,AEK_1

MOV BEK,AX

MOV R8,AX

MOV AX,R1

MOV EK_1,AX

MOV AX,R2

MOV AEK_1,AX

TEST R1,8000H

JZ EK1

NEG R1

EK1: MOV

AX,R1

SUB AX,IBAND

JC II

MOV R3,00H

JMP DDD

II: MOV

MOV AH,00H

MOV CX,R1

MUL CX

MOV CX,KII

DIV CX

MOV R3,AX

TEST R0,8000H

JZ DDD

NEG R3

DDD: TEST

BEK,8000H

JZ DDD1

NEG BEK

DDD1:

MOV AX,BEK

MOV CX,KDD

MUL CX

PUSH AX

PUSH DX

MOV

MOV AH,00H

MOV CX,0008H

MUL CX

MOV CX,AX

POP DX

POP AX

DIV CX

MOV R4,AX

TEST R8,8000H

JZ DD1

NEG R4

DD1: MOV

AX,R3

ADD AX,R4

MOV R5,AX

JO L9

L2: MOV

AX,R5

ADD AX,R2

MOV R6,AX

JO L3

L5: MOV

AX,R6

MOV CX,KPP

IMUL CX

MOV CX,1000H

IDIV CX

MOV CX,AX

RCL AH,01H

PUSHF

RCR AL,01H

POPF

JC LLL1

CMP CH,00H

JZ LLL2

MOV

JMP LLL2

LLL1:

CMP CH,0FFH

JZ LLL2

MOV AL,80H

LLL2:

MOV R7,AL

ADD AL,CK_1

JO L8

L18: MOV

CK_1,AL

ADD AL,80H

MOV

RET

L8: TEST

R7,80H

JNZ L17

MOV

JMP L18

L17: MOV

AL,80H

JMP L18

L9: TEST

R3,8000H

JNZ L1

MOV R5,7FFFH

JMP L2

L1: MOV

R5,8000H

JMP L2

L3: TEST

R2,8000H

JNZ L4

MOV R6,7FFFH

JMP L5

L4: MOV

R6,8000H

JMP L5

CODE ENDS

END START

四 实验步骤

1. 按图接线,电热烤箱接在220V上,插好温度计

2. 装入参考程序,运行程序

3. 设定参数,注意:参考程序的头两条语句是 MOV AX,DATA , MOV DS,AX ,可以获知DS的确切值,根据参数的设置位置,可对参数进行设定和修改。

需要设定的参数值有:

l 烤箱期望达到的温度 SPEC

l PID算法中积分分离值积分分离值 IBAND

l PID算法中比例项系数 KPP

l PID算法中积分项系数值 KII

l PID算法中微分项系数值 KDD

4. 打开示波器窗口,观察温度变化

5. 修改PID参数,观察实验结果

|

项目 参数 |

IBAND |

KPP |

KII |

KDD |

超调 |

稳定<2%时间 |

|

参考程序中参数及响应特性 |

0060H |

1F60H |

0010H |

0020H |

10% |

10分钟 |

|

去掉 IBAND |

0000H |

1060H |

0010H |

0020H |

|

|

|

自测一组较好参数 |

|

|

|

|

|

|

五 参考程序参数表

|

符号 |

单位 |

取值范围 |

名称及作用 |

|

TS |

10mS |

00H~FFH |

采用周期,决定每采集一次数据的时间 |

|

SPEC |

℃ |

14H~FAH |

设定:期望电烤箱达到的温度 |

|

IBAND |

|

0000H~007FH |

积分分离值:PID算法中积分分离值 |

|

KPP |

|

0000H~1FFFH |

比例系数:PID算法中比例项系数 |

|

KII |

|

0000H~1FFFH |

积分系数:PID算法中积分项系数值 |

|

KDD |

|

0000H~1FFFH |

微分系数:PID算法中微分项系数值 |

|

CH1 |

|

00H~FFH |

通道1值:在示被器功能中所显示值需放入此单元中然后再调用 PUT_COM 发送子程序 |

|

CH2 |

|

00H~FFH |

通道2值:(同上) |

|

YK |

N/s |

0000H~0042H |

反馈:通过热敏电阻反馈算出的电烤箱的温度值 |

|

CK |

|

00H~FFH |

控制量:PID 算法产生用于控制的量 |

|

TKMARK |

|

00H~01H |

采样标志位 |

|

ADMARK |

|

00H~01H |

A/D转换结束标志位 |

|

ADVALUE |

|

00H~FFH |

A/D转换结果单元 |

|

TC |

|

00H~FFH |

采样周期变量 |

|

FPWM |

|

00H~01H |

PWM脉冲中间标志位 |

|

CK_1 |

|

00H~FFH |

控制量变量:记录上次控制量值 |

|

EK_1 |

|

0000H~FFFFH |

PID偏差:E(K) = SPEC(K) - YK(K) |

|

AER_1 |

|

0000H~FFFFH |

ΔE(K) = E(K) – E(K-1) |

|

BEK |

|

0000H~FFFFH |

ΔΔE(K) = ΔE(K) –ΔE(K-1) |

|

AAAH |

|

00H~FFH |

用于PWM 脉冲高电平时间计算 |

|

VAA |

|

00H~FFH |

AAAH变量 |

|

BBBL |

|

00H~FFH |

用于PWM 脉冲低电平时间计算 |

|

VBB |

|

00H~FFH |

BBBL变量 |

|

MARK |

|

00H~01H |

|

|

R0~R8 |

|

|

PID 计算用变量 |

六 技术支持: